Templates Community /

PID Controller Basics

PID Controller Basics

Kiraaaa

Published on 2021-06-04

1. Introduction

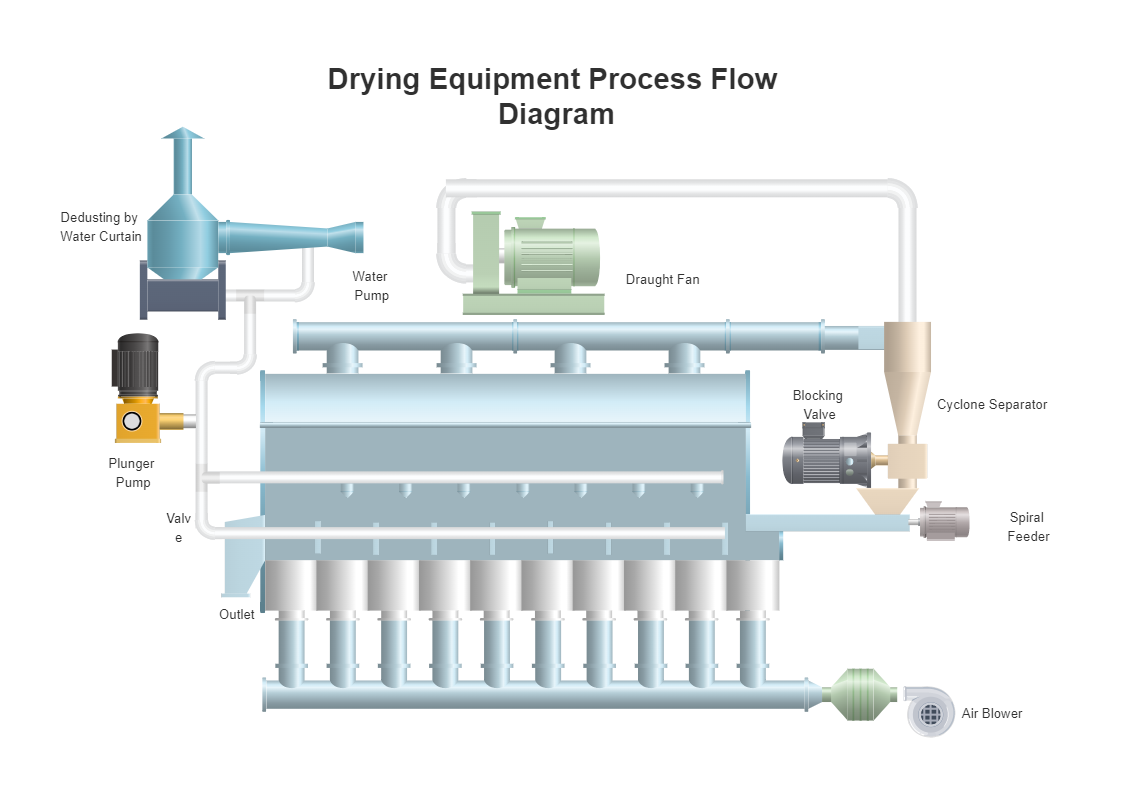

PID controllers are devices used to regulate the temperature in a system. They are majorly used in industrial applications. Also, they have multiple uses in the chemical industry as they regulate pressure, speed, and other variables as well. The PID controller used a feedback mechanism to regulate the different variables in the system.

2. What is PID Controller Basics

The PID Controller Basics circuit works based on proportional, integral, and derivative algorithms.

1) Proportional response: There is a preset value in the system and this component depends on the difference between the set value and the process variable. The difference generated is termed an error term in this system, and if we increase the proportional gain in this circuit, the control system’s speed will rise. But, if the proportional gain becomes too large, it starts oscillating.

2) Integral response: This performs the function of doubling the error term. The integral component will increase slowly even if a small error is generated. It keeps on increasing if the error term is not zero. So, the action plan here is to get the steady-state error zero.

3) Derivative Response: In case the process variable increases gradually, the output will increase. The control system will react more strongly to all changes in the error term. If the sensor feedback signal is noisy or if the control loop rate is too slow, the derivative response can make the control system unstable.

3. How to Create a PID Controller

Creating a PID Controller Basics in EdrawMax Online is pretty simple. The free PID Controller maker has several features as you can instantly import the images or icons from your system or Google Drive, or DropBox. Your PID diagram will require additional media content, making it more creative.

Step 1: Login EdrawMax Online

Log in EdrawMax Online using your registered email address. If this is your first time accessing the tool, you can create your personalized account from your personal or professional email address.

Step 2: Choose a template

EdrawMax Online comes with hundreds of free diagram templates. Select a pre-designed template by entering the Keyword in the ""Search"" section or exploring different diagram sets. In this case, you will find different types of PID controllers under the ""Industrial Process"" section under the ""Engineering"" section. Alternatively, you can simply click on ""+"" in EdrawMax Online canvas to create a diagram of your preference.

Step 3: Work on your research

Based on your research, you will learn that the PID Controller Basics is an instrument used in industrial control applications to regulate temperature, flow, pressure, speed and other process variables.

Step 4: Customize the diagram

Customize your PID diagram by changing the color or adding more relevant data. You can also add or remove the PID Controlling symbols or content accordingly based on your research. Since it is about scientific research, you can add more relevant data about different PID diagrams.

Step 5: Export & Share

Once your required PID diagram is completed, you can share it amongst your colleagues or clients using the easy export and share option. You can further export the diagram in multiple formats, like Graphics, JPEG, PDF, or HTML. Also, you can share the designs on different social media platforms, like Facebook, Twitter, LinkedIn, or Line. In simple words, you can export your incredible PID Controlling diagrams to the files you want with just a few clicks.

Tag

PID Collection

process pid

flowchart

Share

Report

12

646

Post

Recommended Templates

Loading