Template Community /

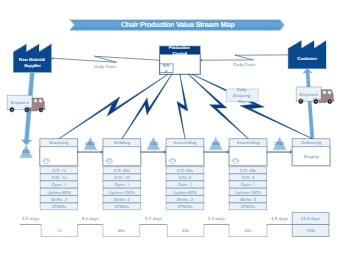

Chair Production Value Stream

Chair Production Value Stream

easy diagrams

Published on 2021-03-31

A Value stream mapping (VSM) is defined as a lean tool that employs a flowchart documenting every step in the process. Usually, several mapping experts consider VSM as a fundamental tool to identify waste, reduce process cycle times, and implement process improvement. As shown in the image below, a chair production value stream mapping starts by showing how a quality material should be used with extreme care, where the timber is passed through the seasoning kiln and converted to standard thicknesses. The logs are sawn into boards, making sure that each log is utilized to the maximum extent. Each part of the chair is made using state-of-the-art equipment and then assembled and sent across the retailers, who in turn put the product on sale for customers to buy.

Tag

Vaule Stream Mapping

Share

Report

6

867

Post

Recommended Templates

Loading