Template Community /

PID Water

PID Water

yandry stanley delgado menoscal

Published on 2021-07-08

1. Introduction

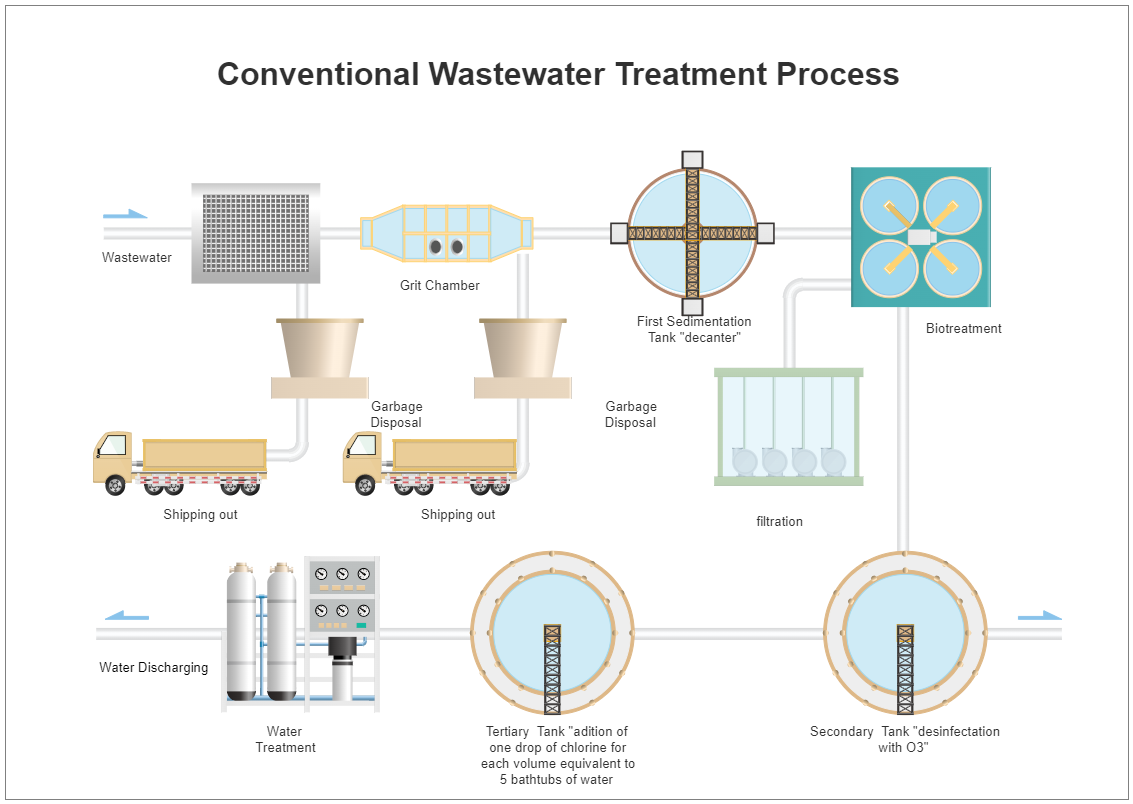

A pipe and instrumentation diagram (P&ID) is a diagram that depicts the piping, vessels, control valves, instrumentation, and other process components and equipment in a process system. The P&ID is the principal schematic drawing for setting out the installation of a process control system. As a result, the P&ID is critical at every stage of the development and operation of a process system.

2. The Usage of PID Water

This project is based on a PID control of a tank's water level. The user has the ability to select a specific level of water, and the system must be able to adjust itself to maintain that level. To that end, a LabView application was created, which allows the user to select the water level, and the output value is changed to be closer to the desired level through frequent recalculations involving the error induced by the input and output values.

3. How to Create a PID Water

Step 1: Define the system's scope.

Do you need to understand the overall process before drawing a P&ID? What does it accomplish?

Step 2: Make a list of the inputs.

Is it a manual or an automatic system? Where do the inputs come from and where do they lead?

Step 3: Determine the outcomes

What is the final result? What are you going to need to make it happen?

Step 4: Make a list of all the equipment involved in the process.

Consider the instruments, control devices, pipelines, and other machinery.

Step 5: Define the components' relationships.

What is their relationship like? Are they a good match?

Step 6: Put your flow together.

Start at the beginning or conclusion of the procedure and work your way through it step by step. What is the next step in the system?

Step 7: Fill in the details

Details on the pipe, component, and instruments, such as measures and diameters, should be added.

Step 8: Go over the steps again.

Keep an eye out for inefficiencies and bottlenecks.

Tag

PID

PID Collection

process pid

Share

Report

71

4.9k

Post

Recommended Templates

Loading