How to Create a Fault Tree Analysis: A Stepwise Tutorial

1. Introduction

Fault tree analysis (FTA) is a visual tool to study the causes of failures in the system. It analyses the system using boolean logic and combines a series of lower-level events. So, let us discuss how to do a fault tree analysis? Fault tree analysis employs a top-down approach to identify.

- Basic event, i.e., component-level failures

- Top event, i.e., the cause of the system-level failure

Fault tree analysis is based on two basic elements: "events" and "logic gates." Logic gates connect events to identify the cause of the failure.

2. What to Know Before Doing a Fault Tree Analysis.

Before going into the details of how to do a fault analysis, it is important to understand the basic constructs and best practices of performing the task. Let us discuss them briefly in this fault tree analysis tutorial.

1. The basic construction component in a fault tree diagram is Gates that are Boolean logic conditions

a. Gates that are Boolean logic conditions

The two most commonly used logical gates in a fault tree analysis are the AND and OR gates.

- OR Gate represents Logical Addition. It means if any of the inputs are 'true, the answer is true. If all inputs are 'false,' only then is the answer false.

- AND Gate represents Logical Multiplication. It means if any of the input is 'false,' then the answer is false. If all inputs are 'true, the answer is true.

b. Events that cause failure.

- The basic event, i.e., component-level failures

- Top event, i.e., the cause of the system-level failure

2. Fault Tree Analysis works well to identify relationships where Boolean relationships exist between inputs, especially in small and medium-sized systems where all causes /events can be conceived.

3. It is critical to have specific data related to known failure rates of components.

4. Always review assumptions and design decisions made during the system design for root cause analysis.

5. Types of fault tree analysis are

- Dynamic FTA

- Repairable FTA

- Extended FTA

- Fuzzy FTA

- State-event FTA

3. How to create a fault tree analysis online?

This fault tree analysis tutorial will teach you how to create fault tree analysis in EdrawMax Online.

Go to EdrawMax Online and create your account to explore the world of drawing and diagramming tools. If you have already registered, log in with your credentials.

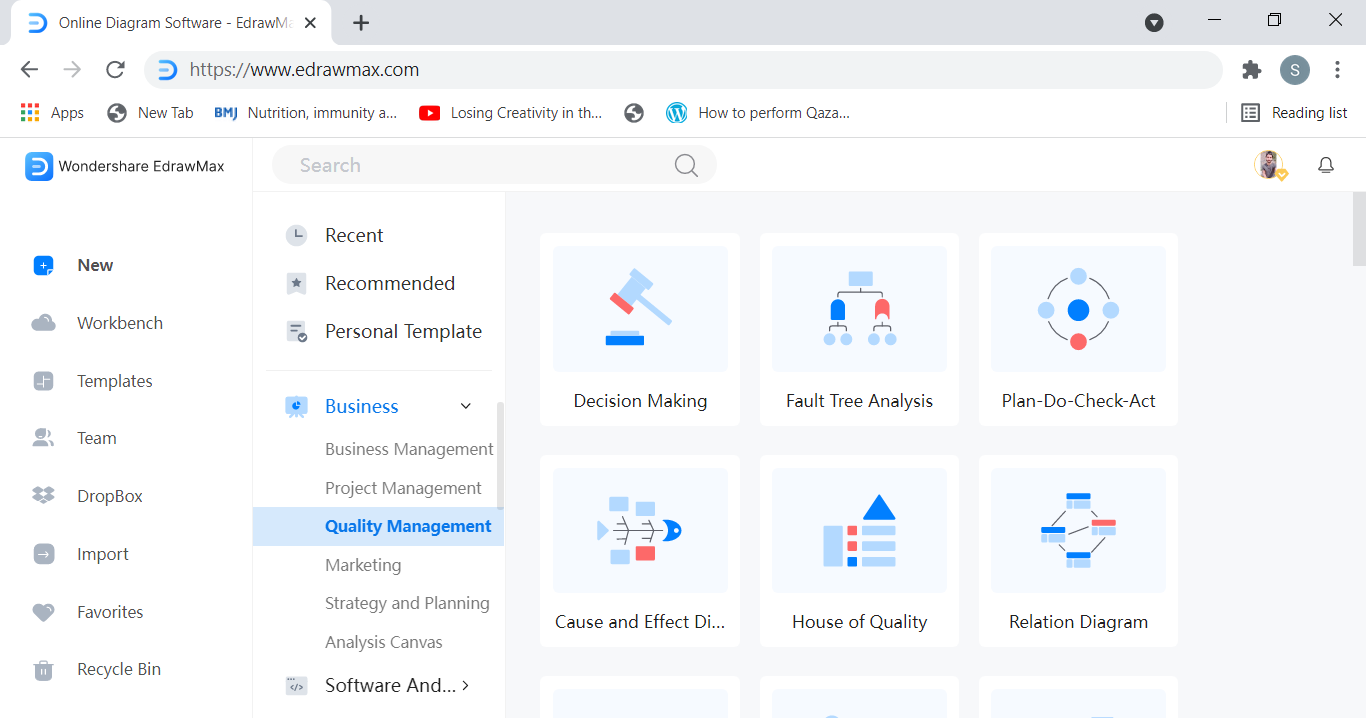

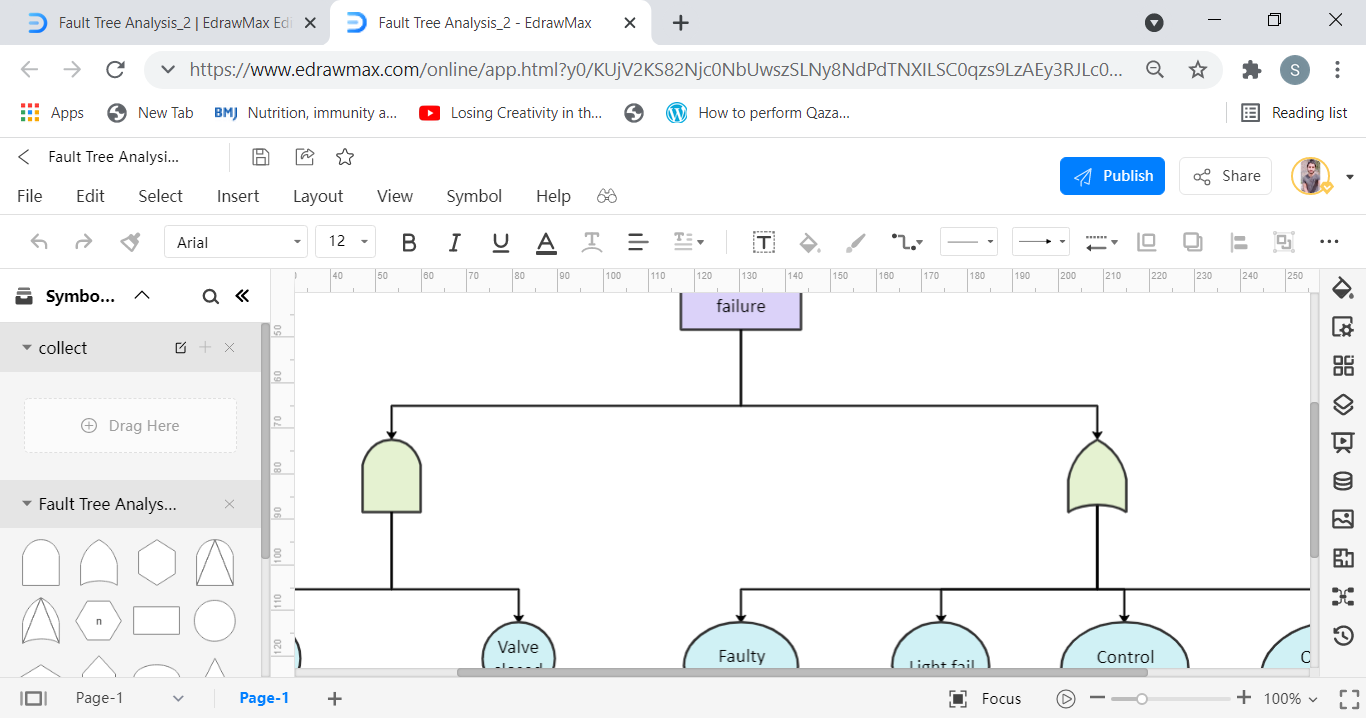

Go to the diagram catalog at New>Business>Quality Management. Click the fault tree management tile to open a clean canvas for creating your diagram.

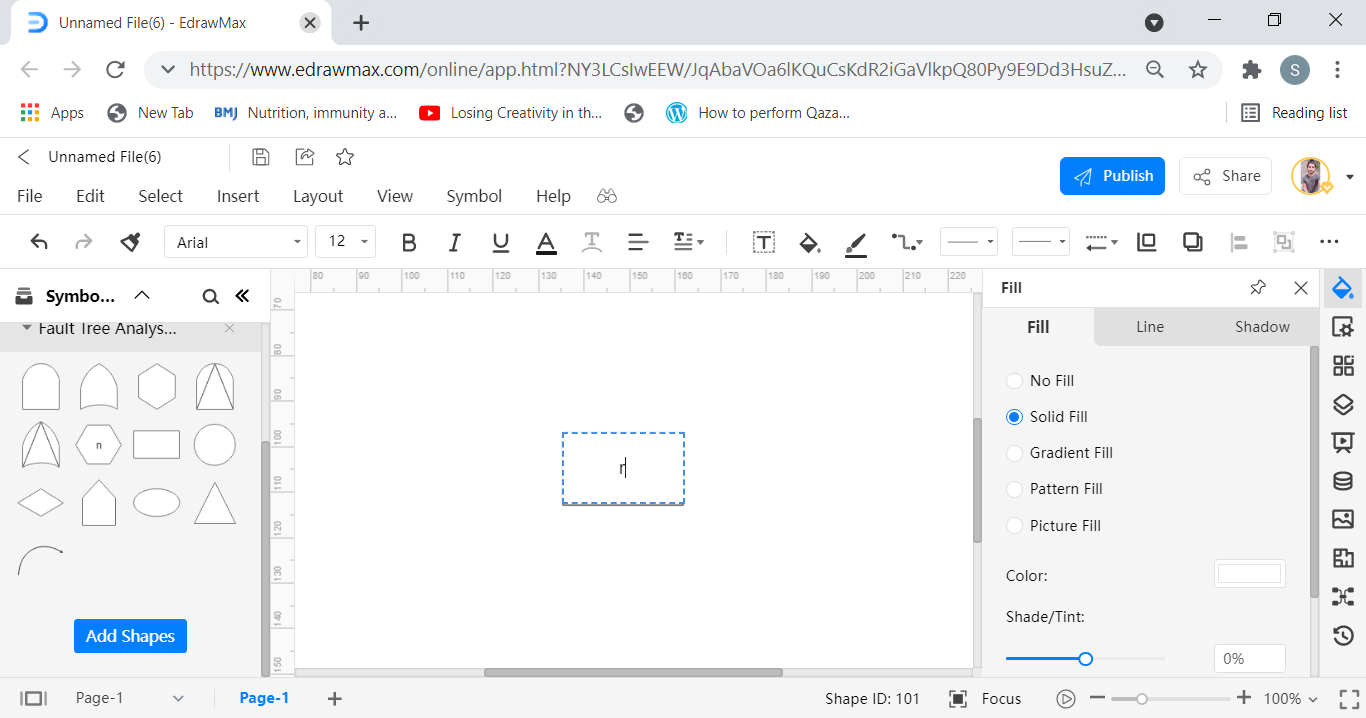

Drag and drop elements in your drawing.

Polish your diagram with drawing tools, theme features, and color scheme. All customization tools are available at the right-hand side pane, including themes for the diagrams, colors, gradients, styles, and other formatting tools.

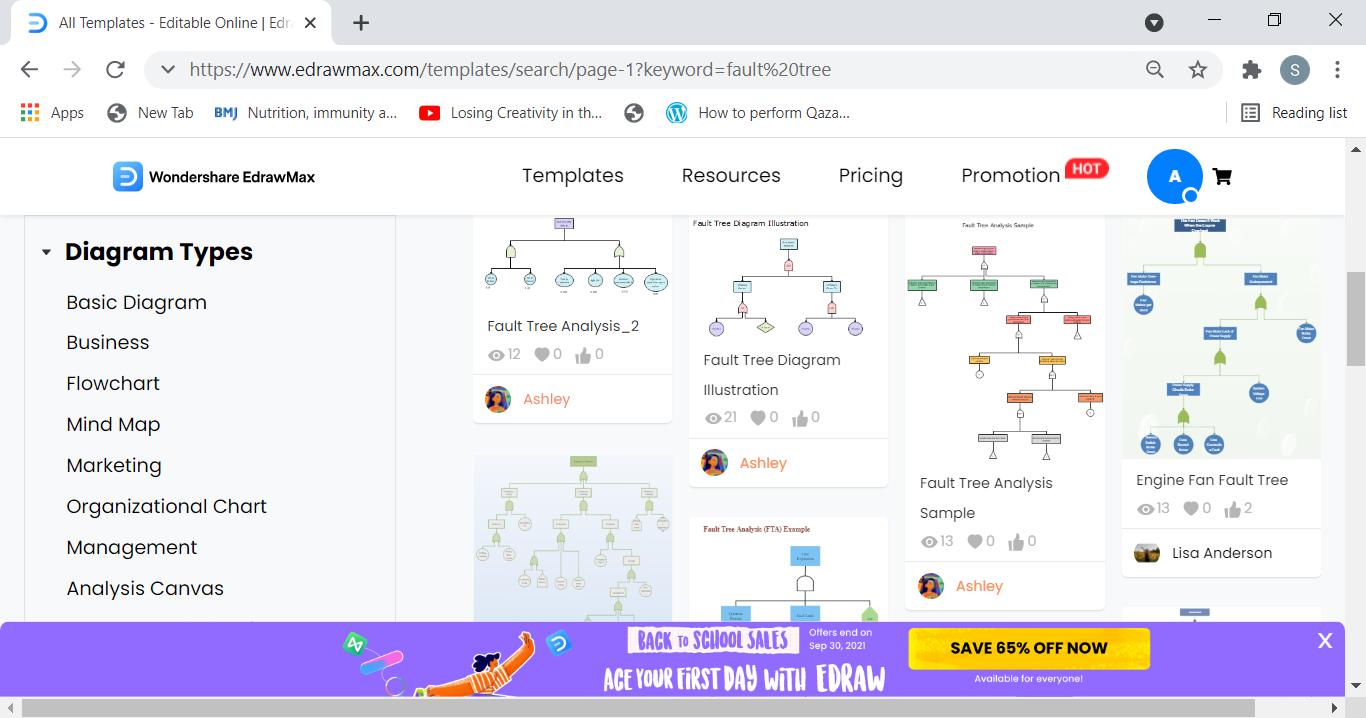

If you do not want to create the diagram from scratch, explore the template library available at templates community. Search for fault tree analysis diagrams and select the most suitable template.

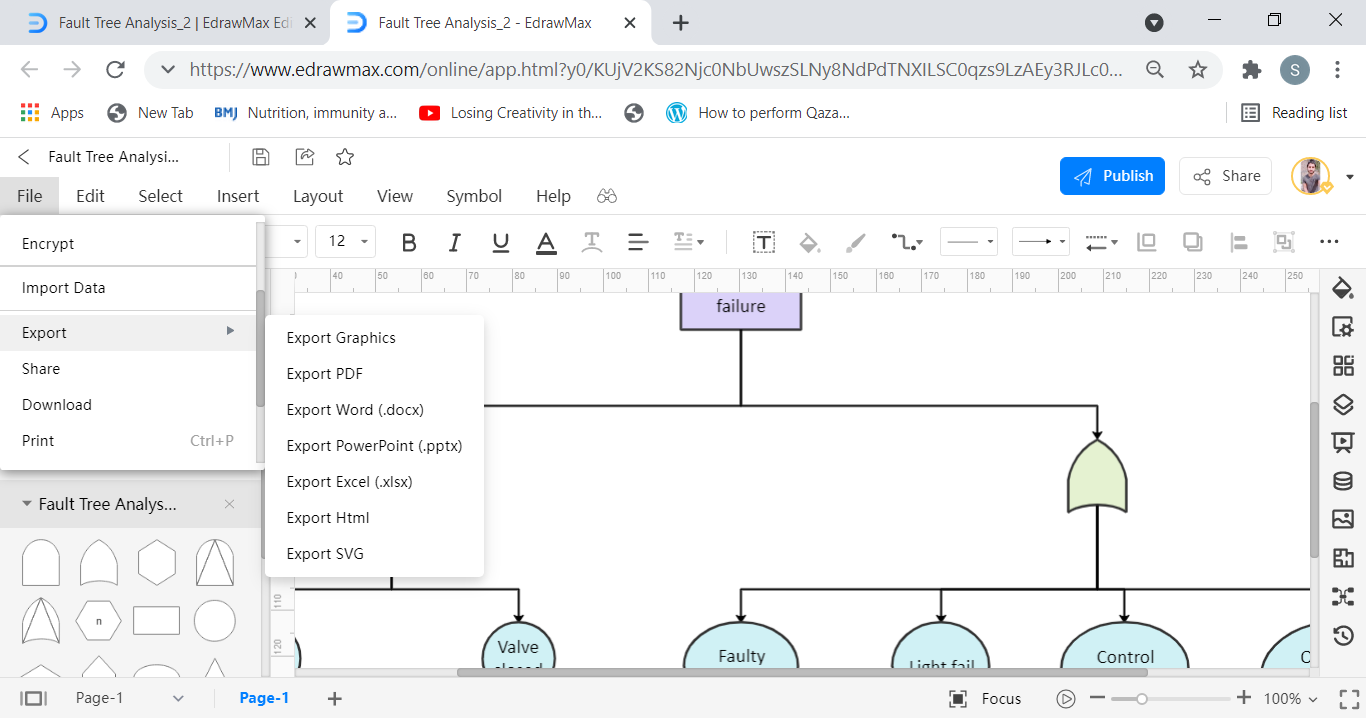

Save your work. You can export your diagram and multiple formats, including PDF, JPEG, PowerPoint, Visio, and so on, for easy distribution and application of your diagrams.

4. Expert Tips for Creating Fault Tree Analysis Diagram

Step 1: Build a diverse team

Building a diverse team of experts from different departments is critical in making an accurate fault tree analysis. The experts must understand the technical aspects of the system. In comparison, the other team members can brainstorm ideas and solutions. Important members of the fault tree analysis team are industrial engineers and system design specialists.

Step 2: Identify failure causes

Identification of failure causes is the first objective of creating failure tree analysis. It is a critical step, and reverse engineering of the basic and top events helps in the identification of issues. Fault tree analysis starts from the top event and then trickles down to identify the root causes. Potential failures with duration, their characteristics, and different impacts of the failure must be defined.

Step 3: Study the inner workings of the system

A deep understanding of the working of a system is a critical aspect when considering how to do fault tree analysis. Brainstorming is the next step to identify all prospective causes of failure.

A professional with knowledge and expertise of the system should guide the discussion to keep it focused. The final required result of this exercise is an understanding of the system's requirements, connections, and dependencies. The team should collect the schematics of the system, documentation of different components, and other available manufacturer information and manuals.

Wondershare EdrawMax

EdrawMax is the easiest diagramming tool that serves all your purposes. Try Free Online now!

5. FAQs About Creating Fault Tree Analysis

What is fault tree analysis used for?

Fault Tree Analysis can be used to assess the risk and probability of an undesirable event you want to prevent. FTA is more commonly employed in the nuclear power industry and military and aerospace industries, where mission success and safety are paramount. Also, the industries employ fault tree analysis to understand, assess, and measure risks and issues.

What is a fault tree analysis diagram?

A fault tree analysis diagram visualizes logical relationships between events and causes leading to failure. It consists of events and Boolean relationships between them to help prioritize issues to fix that contribute to a failure.

What is the difference between fault tree analysis and FMEA?

Fault Tree Analysis(FTA) and Failure Mode and Effects Analysis (FMEA) are tools for root cause analysis, fault-finding, and risk analysis; however, the approach has some differences.

| FTA | FMEA |

|---|---|

| It is a quantitative and tip-down approach | It is a qualitative and button-up approach |

| FTA represents the correlation between multiple failures | FMEA approaches each component of the system individually and does not analyze the system as a whole |

| It involves external events too | FMEA disregards external influences entirely |

| It can be easily updated with software programs like EdrawMax | Often consists of a spreadsheet that needs constant modification |

6. Key Takeaways

Fault tree analysis is a visual tool for performing a system-level risk assessment. It effectively identifies the causes of system failure and allows risk mitigation beforehand. It is usually employed in complex systems because it can visually display the logical way of identifying the problem. It is most commonly used in aerospace, automobile, chemical, nuclear and software industries that involve reliability and safety-related events.

A software program with diagramming tools and easy-to-use layout and functionality is required for creating clean-looking, effective and accurate fault tree analysis diagrams. EdrawMax Online is an excellent choice if you are looking for how to do a fault tree analysis online. It is easy to use, has many templates, and has a wide symbol and media library for easy customization. It is a free and fully featured program you can use through your browser without even downloading it.